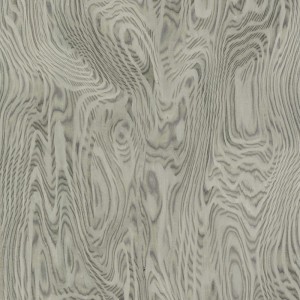

Reconstituted Veneer for Furniture and Interior Decoration

Details You May Want To Know

| Choices of Reconstituted veneer | Over 300 different kinds to choose |

| Thickness of veneer skin | Vary from 0.18mm to 0.45mm |

| Kinds of export packing | Standard export packages |

| Loading quantity for 20’GP | 30,000sqm to 35,000sqm |

| Loading quantity for 40’HQ | 60,000sqm to 70,000sqm |

| Minimum order quantity | 300sqm |

| Payment term | 30% by TT as deposit of order, 70% by TT before loading or 70% by irrevocable LC at sight |

| Delivery time | Normally about 7 to 15 days, it depends on quantity and requirement. |

| Main countries that export to at the moment | Philippines, Thailand, Malaysia, Singapore, Indonesia, Taiwan, Nigeria |

| Main customer group | Wholesalers, furniture factories, door factories, whole-house customization factories, cabinet factories, hotel construction and decoration projects, real estate decoration projects |

Applications

Furniture manufacturing: Reconstituted veneer is commonly used in the production of furniture, including tables, chairs, cabinets, and desks. It can provide a cost-effective and consistent option for achieving desirable wood grain patterns and colors.

Interior design: Reconstituted veneer is used in various interior design applications, such as wall paneling, decorative screens, and room dividers. Its consistent pattern and color make it a popular choice for creating visually appealing and cohesive interior spaces.

Cabinetry: Reconstituted veneer is frequently used in the manufacturing of kitchen cabinets, bathroom vanities, and other storage units. It offers a cost-effective alternative to natural wood veneer while still providing an attractive finish.

Architectural applications: Reconstituted veneer can be used in architectural applications such as doors, window frames, and wall cladding. It provides a consistent and durable surface that replicates the look of natural wood, offering an aesthetic appeal to various building projects.

Musical instruments: Reconstituted veneer can be used in the manufacturing of musical instruments, such as guitars, violins, and pianos. It offers stability, consistent appearance, and can provide an alternative to more expensive and rare wood options.

Musical instruments: Reconstituted veneer can be used in the manufacturing of musical instruments, such as guitars, violins, and pianos. It offers stability, consistent appearance, and can provide an alternative to more expensive and rare wood options.

Overall, reconstituted veneer has numerous applications in furniture design, interior decoration, architecture, and other industries where the appearance of natural wood is desired but with the added benefits of consistency, cost-efficiency, and durability.